Theipi ea Boima ea Boima ba ho Romela bakeng sa ho Tsamaisa Sephutheloana, Ofisi le Polokelo

Lintlha tsa Sehlahisoa:

E koahetsoe ka ho lekana ka emulsion e khomarelang khatello ka mor'a ho futhumatsa, filimi ea BOPP e le thepa ea motheo.

Viscosity e matla; matla a phahameng a tensile; ho hanyetsa boemo ba leholimo bo botle; e sebetsang ho mocheso o pharaletseng oa mocheso;

Kopo :

E sebelisoa haholo ho paka mabokose, likarolo tse ling tse tsitsitseng, lintho tse bohale tse tlamiloe le moralo oa bonono.

| Ntho | Khoutu | Tšehetso | Sekgomaretsi | Botenya(mm) | Matla a Tensile (N/cm) | Bolo ea ho raha (No.# ) | Ho tšoara matla (h) | Elongation(%) | 180° matla a peel (N/cm) |

| Bopp Packing Tape | XSD-OPP | Filimi ea Bopp | Acrylic | 0.038mm-0.065mm | 23-28 | 7 | >24 | 140 | 2 |

| Super Clear Packing Tape | XSD-HIPO | Filimi ea Bopp | Acrylic | 0.038mm-0.065mm | 23-28 | 7 | >24 | 140 | 2 |

| Theipi ea ho paka ka mebala | XSD-CPO | Filimi ea Bopp | Acrylic | 0.038mm-0.065mm | 23-28 | 7 | >24 | 140 | 2 |

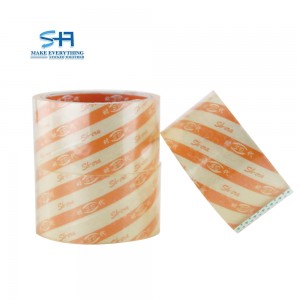

| Theipi e Pakang e hatisitsoeng | XSD-PTPO | Filimi ea Bopp | Acrylic | 0.038mm-0.065mm | 23-28 | 7 | >24 | 140 | 2 |

| Theipi e tsitsitseng | XSD-WJ | Filimi ea Bopp | Acrylic | 0.038mm-0.065mm | 23-28 | 6 | >24 | 140 | 2 |

Histori

Theipi ea 1928 ea Scotch, Richard Drew, St. Paul, Minnesota, USA

E sebelisa ka la 30 May, 1928 United Kingdom le United States, Drew o ile a etsa sekhomaretsi se bobebe haholo, se tšoarang hanngoe feela. Boiteko ba pele ha boa ka ba khomarela ka ho lekaneng, kahoo Drew o ile a bolelloa: “Khutlisetsa ntho ena ho beng ba hao ba Scotland ’me u ba kōpe hore ba kenye sekhomaretsi se eketsehileng!” (“Scotland” e bolela “ho nyonya.” Empa nakong ea Ho oa ho Hoholo ha Moruo, batho ba ile ba fumana tšebeliso e makholo bakeng sa teipi ena, ho tloha ho lokiseng liaparo ho isa ho ho sireletsa mahe.

Hobaneng ha teipi e ka khomarela ho hong? Ha e le hantle, ke ka lebaka la lera la sekhomaretsi holim'a lona! Likhomaretsi tsa khale ka ho fetisisa li ne li tsoa liphoofolong le limela. Lekholong la leshome le metso e robong la lilemo, rabara e ne e le eona karolo e ka sehloohong ea likhomaretsi; athe mehleng ea kajeno, li-polymer tse fapaneng li sebelisoa haholo. Likhomaretsi li ka khomarela lintho, hobane limolek'hule ka botsona le limolek'hule tse lokelang ho kopanngoa ho etsa tlamo, mofuta ona oa tlamo o ka khomarela limolek'hule hammoho ka thata. Sebopeho sa sekhomaretsi, ho ea ka mefuta e fapaneng le mefuta e fapaneng, se na le lipolymer tse fapaneng tse fapaneng.

Tlhaloso ea Sehlahisoa

Theipi ea ho tiisa e boetse e bitsoa tepi ea bopp, tepi ea ho paka, joalo-joalo E sebelisa filimi ea BOPP biaxially oriented polypropylene e le thepa ea motheo, 'me ka ho lekana e sebelisa emulsion e khomarelang khatello ka mor'a ho futhumatsa ho theha 8μm--28μm. Adhesive layer ke ntho ea bohlokoa bophelong ba likhoebo tse bobebe tsa indasteri, lik'hamphani le batho ka bomong. Naha ha e na maemo a phethahetseng bakeng sa indasteri ea litheipi Chaena. Ho na le tekanyetso e le 'ngoe feela ea indasteri "QB/T 2422-1998 BOPP tepi e khomarelang khatello ea khatello bakeng sa ho tiisa" Ka mor'a phekolo ea khatello e phahameng ea corona ea filimi ea pele ea BOPP, ho thehoa sebaka se thata. Ka mor'a ho sebelisa sekhomaretsi ho eona, moqolo oa jumbo o thehoa pele, ebe o khaola ka meqolo e menyenyane ea litlhaloso tse fapaneng ka mochine oa ho senya, e leng tepi eo re e sebelisang letsatsi le leng le le leng. Karolo e ka sehloohong ea emulsion e khomarelang khatello ea maikutlo ke butyl ester.

Likarolo tse ka Sehloohong

Litheipi tsa boleng bo holimo le tse sebetsang hantle li na le ts'ebetso e ntle esita le maemong a leholimo a thata ka ho fetesisa, a loketseng ho boloka thepa matlong a polokelo, lijana tsa ho tsamaisa thepa, ho thibela bosholu ba thepa, ho buloa ho seng molaong, joalo-joalo Ho fana ka mebala e ka bang 6 le boholo bo fapaneng. tepi

Matla a sekhomaretsi hanghang: tepi e tiisang e a khomarela ebile e tiile.

Bokhoni ba ho lokisa: Le ha o na le khatello e nyane haholo, e ka ts'oaroa ho workpiece ho latela mehopolo ea hau.

Ho tabola habonolo: ho bonolo ho tabola moqolo oa theipi ntle le ho otlolla le ho hula tepi.

Ho phutholoha ho laoloang: Theipi e tiisang e ka huleloa hole le moqolo ka mokhoa o laolehileng, eseng e hlephileng kapa e thata haholo.

Flexibility: Theipi e tiisang e ka ikamahanya habonolo le sebopeho sa curve se fetohang ka potlako.

Mofuta o mosesaane: Theipi e tiisang e ke ke ea siea li-deposit tse teteaneng.

Smoothness: Theipi e tiisang e boreleli ho fihlela ha e theoa 'me ha e khopise letsoho la hau ha e hatelloa ka letsoho.

Anti-transfer: ha ho sekhomaretsi se tla sala ka mor'a hore tepi ea ho tiisa e tlosoe.

Solvent resistance: Thepa e tšehetsang theipi e tiisang e thibela ho kenella ha solvent.

Anti-fragmentation: Theipi e tiisang e ke ke ea peperana.

Anti-retraction: Theipi e tiisang e ka otlolloa sebakeng se kobehileng ntle le ts'ebetso ea ho hula.

Anti-stripping: Pente e tla tlamelloa ka thata ho thepa e tšehetsang tepi e tiisang.

Kopo

E loketse ho paka ka kakaretso sehlahisoa, ho tiisa le ho tlama, ho paka limpho, jj.

'Mala: Letšoao la khatiso lea amoheleha ho latela litlhoko tsa bareki.

Theipi ea ho tiisa e hlakileng e loketse ho paka li-carton, ho lokisa likarolo, ho kopanya lintho tse bohale, moralo oa bonono, joalo-joalo;

Theipi ea ho tiisa mebala e fana ka mebala e sa tšoaneng ho finyella litlhoko tse fapaneng tsa ponahalo le botle;

Theipi e tiisang ea khatiso e ka sebelisoa bakeng sa ho tiisa khoebo ea machaba, lisebelisoa tse hlakileng, mabenkele a marang-rang, lihlahisoa tsa motlakase, lieta tsa liaparo, mabone a bonesang, thepa ea ka tlung le mefuta e meng e tsebahalang. Tšebeliso ea theipi ea ho tiisa ho hatisa e ke ke ea ntlafatsa setšoantšo sa letšoao feela, empa hape le ho finyella Phatlalatso ea Mass Media Informing.